Who we are

Since 1928 Bonomi’s production units are specialised in the engineering and production of solutions to support electrical conductivity and insulation. Our particular expertise lies in the railway, energy and custom sectors. Over the last 10 years’ the group has broadened its product base and expertise by acquisition, establishing itself as an international market leader.

Vision

We are committed to developing technical and productive skills in the sector of electrical conduction applied to the world of rail, energy, electromechanical and custom.

We work every day to set the standards in a context of continuous infrastructure growth and to oversee the whole supply chain (from engineering to the production of every single component). We ensure high quality certified raw materials, a very high technical know-how and a high flexibility in terms of customization.

We work every day to set the standards in a context of continuous infrastructure growth and to oversee the whole supply chain (from engineering to the production of every single component). We ensure high quality certified raw materials, a very high technical know-how and a high flexibility in terms of customization.

Mission

Our key success factors are know-how, technical specialization and our production flexibility.

We cultivate talent, invest in research and development and allocate every year part of our turnover in the renewal of our plants.

We cultivate talent, invest in research and development and allocate every year part of our turnover in the renewal of our plants.

Our history

'900 - The beginning

Start of the production

process for taps and

valves by Serafino

Bonomi.

1920 - EB Rebosio

Foundation year of

R.I.E., now Rebosio.

1928 - The foundry

Conversion into a foundry

for non-ferrous alloys.

'50 - '60 - Electromechanical department

Start-up of the electromechanical department

Bonomi specialized in components with

application in electrical conduction. In the

same period, Rebosio is among the first

manufacturers in Europe to introduce silicone

composite insulators.

'70 - '80 - Railway department

Bonomi Eugenio SPA enters the rail

sector. Rebosio increases silicone

composite insulators production.

1999 - New production site

Bonomi Eugenio

SPA production

site moves to

Montichiari (the

current company

headquarters).

2002 - Group

Bonomi aquires

Rebosio Srl.

2008 - OMNIA

Bonomi (in collaboration

with GCF and Satferr) design

and produce OMNIA, the

first smart cantilever which

has now been approved in

Italy and UK.

Joint venture starts with the

Chinese company Bao De Li.

2011 - Turkey

EB Rebosio

opens a

production

facility in Turkey.

2012 - Isoelectric

Isoelectric becomes

part of the Bonomi

Group , adding

additional production

capacity through its

plant in Brazil.

Productive Know-How

We have the know-how of different technologies and materials.

The structure of the group allows us to transform silicone, resin and

non-ferrous alloys, ensuring a unique and highly controlled supply

chain. In this way we are able to offer extremely cost effective

solutions and timely responses to the clients. Moreover,

in Bonomi we invest every year to have the latest generation plants.

non-ferrous alloys, ensuring a unique and highly controlled supply

chain. In this way we are able to offer extremely cost effective

solutions and timely responses to the clients. Moreover,

in Bonomi we invest every year to have the latest generation plants.

Internal production:

- Casting

- Hot forging

- Blaking and coining

- CNC and robot machining

- Silicone and epoxy resin injection

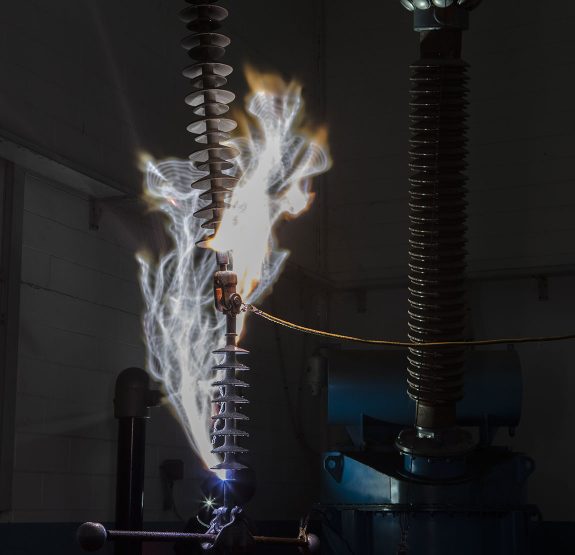

Test rooms

Mechanical, chemical and electrical

We undertake the following functions in house:

- dimensional checks with electronic systems

- hardness checks

- roughness checks

- galvanic coatings checks

- mechanical tests of traction, compression, flexion and torsion, also combined with thermal cycles

- fatigue tests

- electrical, insulation (industrial frequency and impulse) and partial discharge tests

- ageing test in salt fog chamber and/or in thermostatic chamber